Uses of Bamboo

What Products are Made from Bamboo?

Bamboo has been used for thousands of years by many cultures around the world. Today we see a boom of innovative bamboo products and applications as a sustainable alternative for wood. Read on and discover some of the coolest bamboo products you probably didn't even know they existed!

What products are made from bamboo? It’s often one of the first questions people ask when they are starting to learn about this amazing plant. I usually answer with the rhetorical question: What products can be made from wood? Fact is, everything that can be made from wood can also be made with bamboo. However, the advantage of bamboo is that it grows incredibly fast, that it can be harvested on an annual basis without damaging or having to re-plant the plantation or forest, and that bamboo has some superior mechanical properties compared to traditional timbers.

There are currently thousands of commercial bamboo products on the market, and new innovative uses and applications are added every day. This goes from construction materials to food, medicine, musical instruments, fabrics, paper pulp, fencing, basketry, utensils, bicycles, and so on… Therefor te better question would be: What products cannot be made from bamboo? Or as the ancient Asian saying goes:

"A man is born in a bamboo cradle and goes away in a bamboo coffin. Everything in between is possible with bamboo!"

A short film commissioned by INBAR for the World Expo in Shanghai, profiling bamboo - and its many innovative uses as a strong, lightweight, sustainable, carbon capturing material, including surfboards, bikes, and building materials. Bamboo is brilliant, just watch the video!

Bamboo Musical Instruments

Bamboo is used to make musical instruments for thousands of years, probably as a percussion instrument at first, but later also for wind instruments and stringed instruments. Its natural hollow form makes bamboo an obvious choice for many traditional instruments such as a wide variety of flutes, but because of the excellent sound properties of solid bamboo panels it is now also used for making modern guitars.

A popular saying is that every bamboo forest hides the instruments for a whole orchestra. The list of musical bamboo instruments is indeed very long and include xylophones, rainsticks, marimbas, angklung, castanets, drum sticks, zithers, slit drums, chimes, maracas, guitars, ukuleles, violins, Chapman sticks, pan flutes, didgeridoos, pipe organs, saxophones, clarinets, kazoos, whistles, trumpets, and piccolos just to name a few.

Bamboo Fabrics and Textiles

In recent years different technologies have been developed that allow bamboo fiber to be used for a wide range of textile, fabrics, yarn, cloth, clothing and fashion applications such as T-shirts, pants, underwear, socks, towels, bedsheets, pillow covers, blankets, mattresses, and even bulletproof vests.

Two manufacturing processes are currently used to make textiles from bamboo: chemical processing and mechanical processing. The advantages of mechanically processed bamboo fabric are its ramie-like feel, its natural antifungal and antimicrobial properties, its quick moisture absorption and drying capabilities, its ability to stay warm in cool weather and cool in warm weather, its ultraviolet protection, and its anti-static nature.

Unfortunately (due to the higher cost of mechanically extracted bamboo fibers), modern bamboo clothing is usually made from chemically processed bamboo, called: viscose rayon. Such rayon is made by dissolving the cellulose in the bamboo, and then extruding it to form fibers. This process removes the natural characteristics of bamboo fiber, rendering it identical to rayon from other cellulose sources. Unless a product is made directly with bamboo fiber (mechanically processed bamboo) it is not allowed be called “bamboo”.

Bamboo textiles present many solutions to the present unsustainable nature of textile engineering as bamboo is a renewable resource that yields 50 times as much fiber per acre as cotton. However, cost, energy, water, and chemical concerns in manufacturing still must be addressed.

Bamboo Pulp and Paper

In China bamboo fiber has been used to make paper since early times, but in recent years, bamboo has emerged as an important raw material for the pulp and paper industry due to the shortage of wood resources. Bamboo paper has a high tear index, similar to that of hardwood paper, and its brightness and optical properties remain stable, while those of wood derived paper may deteriorate over time. Bamboo can also be pulped with less power and chemicals than wood which makes it more environmental friendly.

The total production capacity of bamboo pulp in China reached 2,4 million tons in 2017, of which 80% of the pulp is used for the production of unbleached bamboo pulp for household paper grades. A few examples of bamboo paper products are coffee filters, paper cups, paper towels, toilet paper, cardboard, kraft paper, and bond paper.

Bamboo Toilet Paper

Bamboo Coffee Filters

Disposable Bamboo Paper Cups

Reusable Bamboo Paper Towels

Bamboo Baby Diapers

Bamboo Copy Paper

Bamboo Bioenergy

Bamboo Chips

Bamboo Charcoal

Bamboo Briquettes

Bamboo Pellets

Bamboo Food and Beverage

Bamboo Sports and Recreation

Bamboo Helmets

Bamboo Skateboard

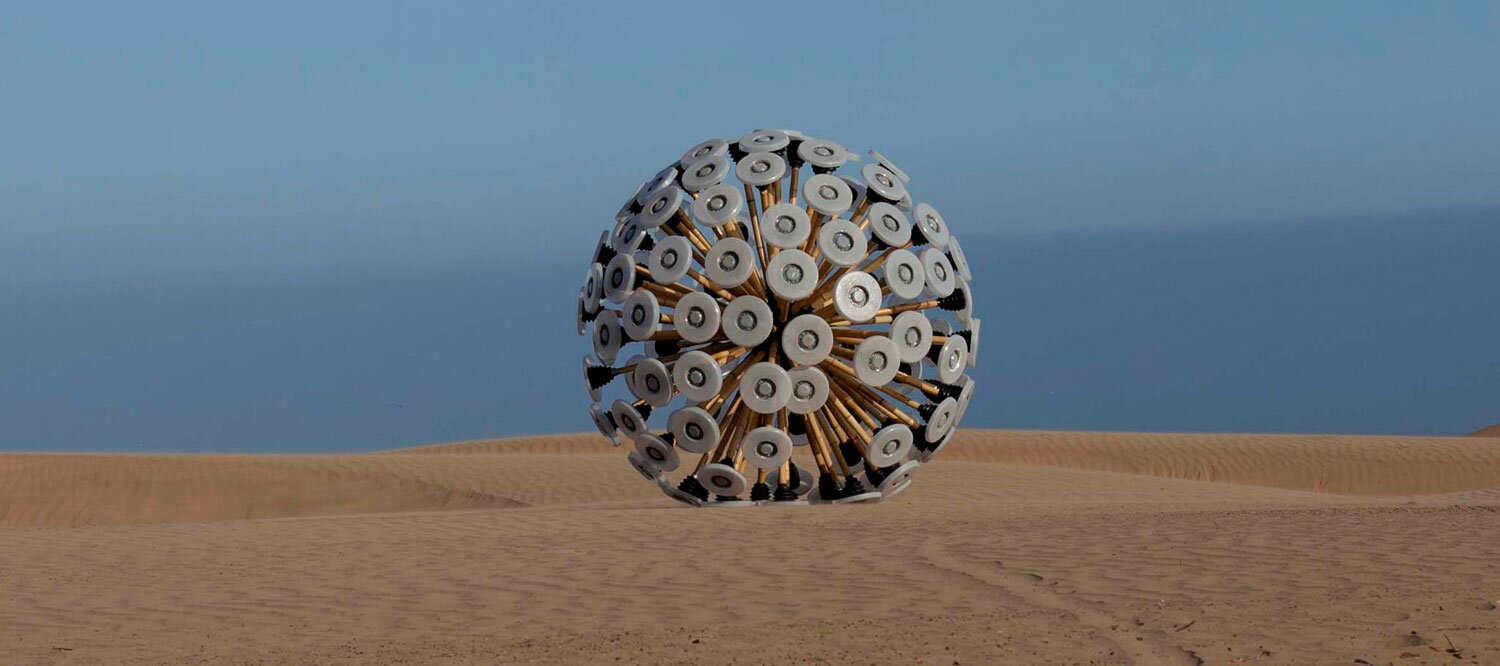

Bamboo Golf Tees

Bamboo Paddleboard Paddle

Bamboo Cornhole Game

Bamboo Bicycle

Bamboo Bottle

Bamboo Luggage Carrier

Bamboo Baseball Bat

Bamboo Ski Poles

In recent years different technologies have been developed that allow bamboo fiber to be used for a wide range of textile, fabrics, yarn, cloth, clothing and fashion applications such as T-shirts, pants, underwear, socks, towels, bedsheets, pillow covers, blankets, mattresses, and even bulletproof vests.